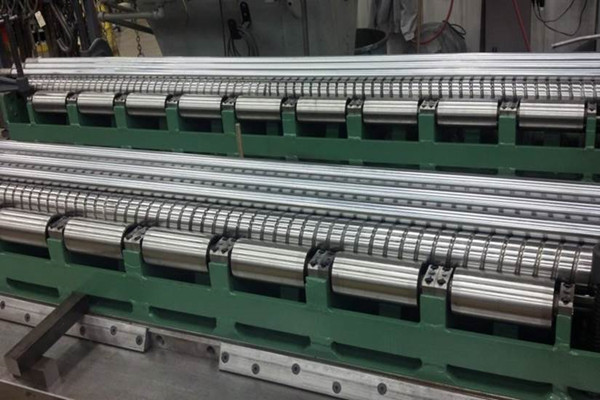

Back-up rollers design and application for a better metal sheet quality

Back-up rollers in tension levelers are key parts which essential to support and limit the movement of the work rolls in order to get excellent quality on the metal sheet as well as reduce potential defects. Aware of the importance of this processing phase, LYSYM uses high quality steel for the production of its back-up rollers for tension levelers, with or without shafts.

To increase the bearing life, it can be ensured that the finished product will be free from imperfections caused by the rollers themselves. The effectiveness of the production process is particularly important in the case of flat products in stainless steel, aluminum and copper, for which the surface finishing represents a fundamental characteristic of the product.

Another issue in the processing of the sheet is caused by unscheduled production lines stoppages due to unforeseen maintenance interventions. Also in this case the fallout on the production cycle is immediate, with delays that impact the production itself. To give a concrete answer to the problem, LYSYM has implemented technological solutions in the production phase of its back-up rollers which have the objective of improving the performance and the useful life of the bearing and consequently extending the maintenance time. Among these we mention the rolling elements with a logarithmic profile, which distribute the hertzian pressures between rolling element and rolling track. The shafts made with special steels improve the toughness and avoid possible fatigue failures that are very common in this type of application.

In order to improve the bearing behavior and extend its life, LYSYM has also adopted axial containment with a cylindrical roller cage.

Concerning the sealing system, the choice is FEY laminar rings, capable to operate with high temperatures and reduce the rolling torques, with the guarantee of very high efficiency throughout the life of the bearing. For the purpose of lengthening the maintenance intervals, a lubrication circuit inside the bearing is specifically designed in order to provide the lubrication of all the axial and radial rolling surfaces. The camber of the outer mantle of the back-up rollers is adopted to counterbalance possible misalignments of the machine supports. LYSYM supplies the rollers in radial or axial-radial versions. Moreover, depending on the type of application, the company can supply, on request, also seals in metal or synthetic material.

How to prolong the service life of bearings

Choose the right bearing

In order to select a more suitable bearing from a large number of structures and sizes, it is necessary to study from various angles. The specific method of bearing selection is as follows:

1. The bearing structure is determined

Considering the ease of arrangement, installation, and disassembly of the bearing as a shaft system, the allowable space and size of the bearing, and the marketability of the bearing, the bearing structure is roughly determined.

2. Service life

While comparing and studying the design life of various machinery using bearings and the various endurance limits of the bearings, the bearing size is determined. When selecting a bearing, it is often biased to consider only the fatigue life of the bearing. The grease life, wear and noise caused by the aging of the grease also need to be fully studied.

3. Determination of bearing use

According to different uses, it is necessary to select specially designed bearings for accuracy, clearance, cage structure, grease, etc. requirements. However, there is no certain order and rules for selecting bearings. The priority should be considered for the requirements of the bearing, performance, and more related matters, which is especially practical.

The effect of heat treatment on the material of cross roller bearing

Crossed roller bearings are a kind of bearings that are used more mechanically, especially in industrial machines. Of course, when we use them, we need to have better performance of crossed roller bearings to ensure the performance of crossed roller bearings. For various properties, then we need to perform heat treatment on its processed materials, so why do we need heat treatment? Let’s take a look! 1. Surface residual stress The distribution of surface residual stress of bearing steel after quenching is largely affected by the cooling rate and quenching medium. For the materials used in crossed roller bearings, heating to 840 ℃…

Causes of temperature rise during use of crossed roller bearings

Crossed roller bearings are also commonly used nowadays. Many machinery and equipment will choose crossed roller bearings. Crossed roller bearings are favored because they have good performance and mainly meet the needs of use. Bearings are always used when they are used. If you want to rotate, it will inevitably generate heat during the rotation, but there is also a situation where the overheating temperature gradually rises.

Let’s take a look! 1. The influence of lubricating oil 1. If the amount of lubricating oil used is too little or too much lubricating grease, it may cause the temperature to rise, so when using it, it should be in accordance with the requirements of usual work…