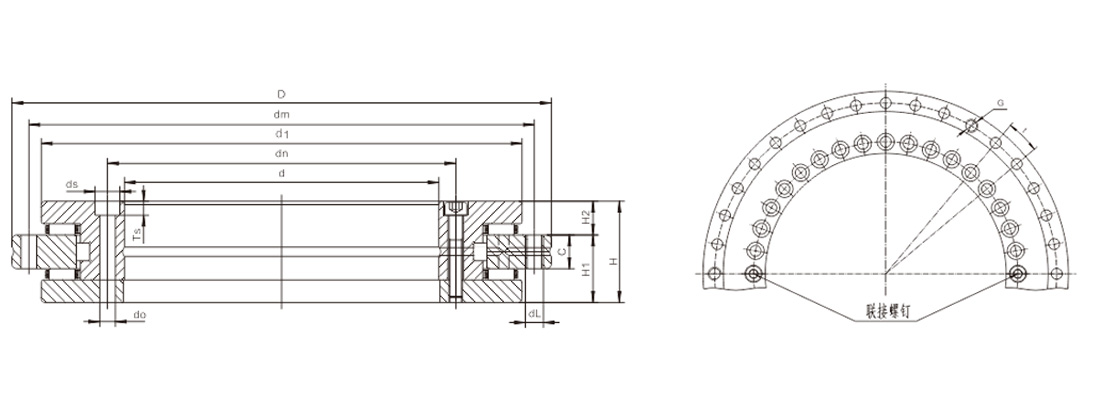

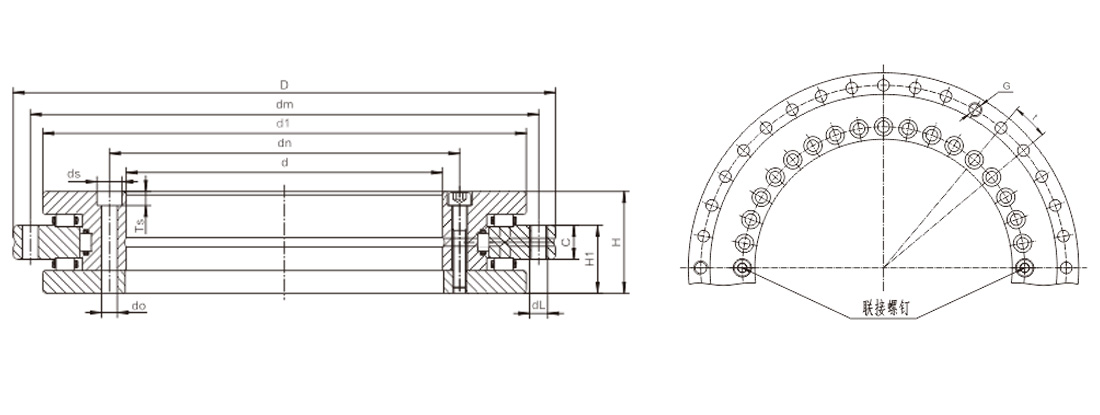

Operating temperature:

YRT bearings are suitable for operating temperatures from 30℃ to 120℃

Design and safety guidelines:

Basic rating life:

Please contact us in relation to checking of the basic rating life .The speed ,load and operating duration must be given.

Static load safety factor:

The static load safety factor S0 indicates the security against impermissible permanent deformations in the bearing. It is determined as follows:

Static load safety factor :Cor Coa N

Basic static load rating according to dimension tables: For Foa N

Maximum static load on the radial or axial bearing.

Caution! In machine tools and similar areas of application, S0 should be >4

Limiting speeds:

The bearings allow the limiting speeds given in the dimension tables. The operating temperatures occurring are heavily dependent on the environmental conditions. Calculation is possible by means of a thermal balance analysis based on frictional torque data.

Frictional torque:

The bearing frictional torque MRL is influenced primarily by the viscosity and quantity of the lubricant and the bearing preload.

The lubricant viscosity and quantity are dependent on the lubricant grade and operating temperature. The bearing preload is dependent on the mounting fits, the geometrical accuracy of the adjacent parts, the temperature difference between the inner and outer ring, the screw tightening torque and the mounting situation.

Starting torque:

For YRT bearing, it must be taken into consideration that the frictional torque can increase by a factor of between 2 and 2.5 with increasing speed.