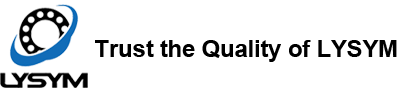

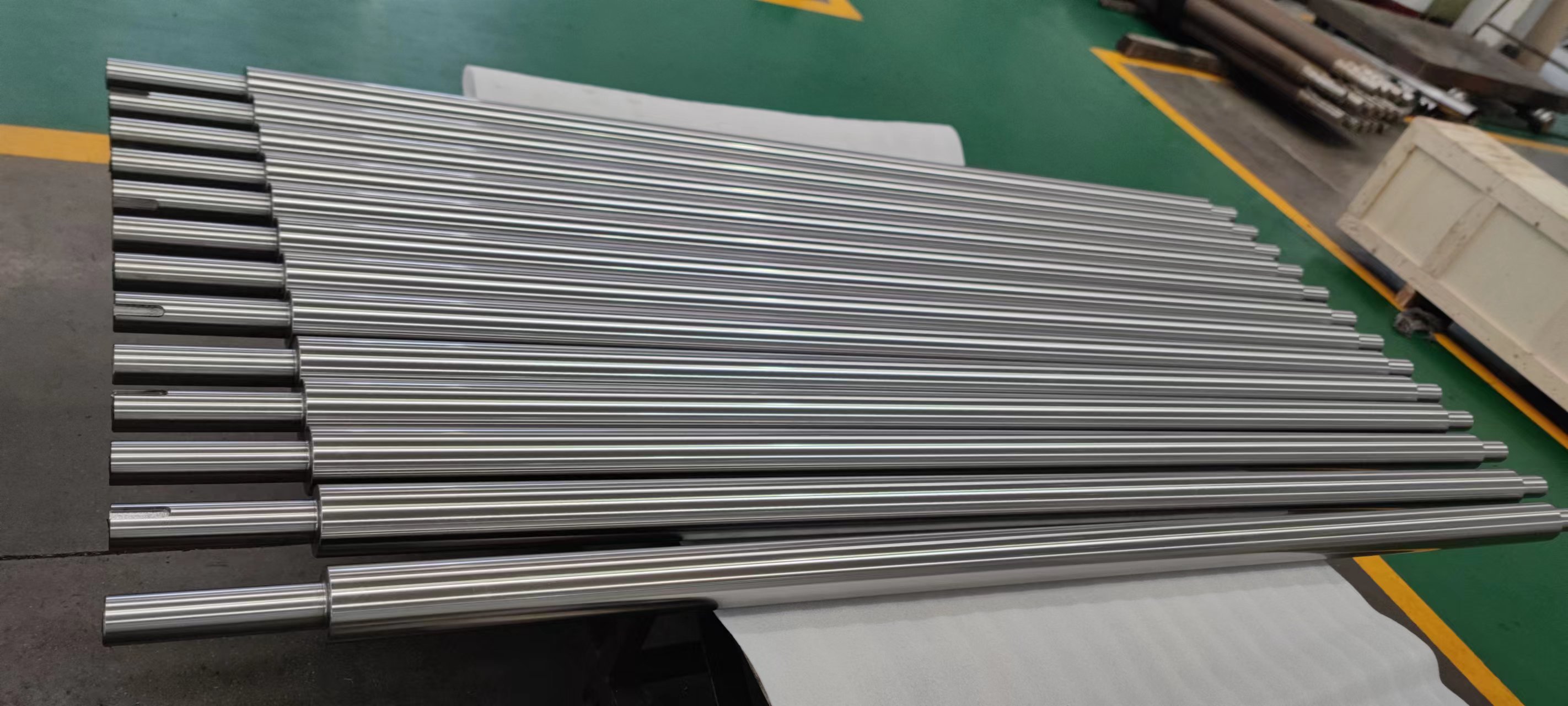

Work rolls for cold rolling mills

Work rolls are the heart of a cold rolling mill. They are the pair of rolls (top and bottom) that make direct contact with the metal strip (usually steel, aluminum, or copper). Their primary function is to apply compressive force to reduce the thickness of the strip by 30-70% in a single pass, while also imparting a desired surface finish and metallurgical properties.

Work rolls operate under extreme conditions, requiring a unique set of properties:

1. Extreme Hardness: Typically 58-65 HRC. Necessary to resist plastic deformation under massive rolling forces (thousands of tons).

2. High Wear Resistance: To maintain precise gauge (thickness) and surface finish over long rolling campaigns.

3. High Toughness: To resist chipping, spalling, and catastrophic failure from thermal and mechanical fatigue.

4. Consistent Microstructure: Usually a fine martensitic matrix with a uniform dispersion of hard carbides (e.g., chromium, vanadium, molybdenum carbides).

5. Precise Dimensional & Geometric Tolerance: Barrel (body) and neck (bearing journal) are machined to micron-level accuracy.

6. Good Thermal Conductivity & Fatigue Resistance: To manage heat generated by deformation and friction.

Material can be 100Cr6, 60CrMoV, 86CrMoV7 as the requirements of customers.

Applications:

• Pickle Lines

• Galvanizing Lines

• Continuous Annealing Lines

• Flatteners

• Heat Treat Levelers

• Plate Mill Levelers

• Steel Processing Lines

• Cut-to-Length Lines

• Aluminum Mills

• Stamping Operations

For more information about work rolls, backup rolls, intermediate rolls, please contact info@lysym-bearing.com.